This article takes a deep dive into the transformative role of manufacturing training software in reshaping skill development – exploring key features, benefits, case studies, and future trends in this technology-driven landscape.

Here’s a bit of unsettling news: Much like numerous other sectors, the manufacturing industry in the United States confronts a significant deficiency in skilled labor. According to a recent survey involving 389 manufacturers, a substantial 85% of respondents indicate grappling with unfilled positions due to a scarcity of suitably qualified candidates. This has resulted in an industry-wide surplus of over 1 million job vacancies.

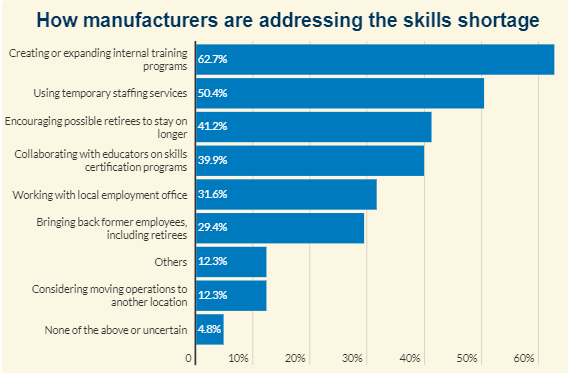

To combat this skills shortage, viable strategies come to the fore. Among the solutions proposed, there is a focus on the following:

- Establishing or expanding in-house training initiatives

- Leveraging the services of temporary staffing agencies

- Forging partnerships with educational institutions to establish skills certification programs

- Encouraging potential retirees to extend their tenure in the workforce

- Developing skills with the help of training software solutions

These measures, among others, aim to mitigate the existing skills gap, fostering a more robust manufacturing workforce.

Among all of the above measures, skill development has become the linchpin in this dynamic environment. Why? The future belongs to those who can swiftly acquire and apply new competencies. To meet this demand, technology takes center stage, catalyzing and reshaping manufacturing training.

With a significant chunk of manufacturers investing in technology-driven training solutions, it’s evident that the industry recognizes the pivotal role technology plays in this transformative journey.

In this exploration, we delve into the near future, where technology-driven solutions like manufacturing training software are not just an option, but the key to staying competitive in a rapidly changing world.

Table of Contents

The Current Landscape of Manufacturing Training

Traditionally, manufacturing training has relied heavily on face-to-face interactions, classroom sessions, and hands-on apprenticeships. Apprenticeships, in particular, have been a cornerstone of the industry, with experienced workers passing down their knowledge and skills to the next generation.

These methods have provided invaluable practical experience and mentorship. However, they have significant limitations, including geographical constraints, inconsistent training quality, and difficulties in maintaining standardized training across diverse locations and facilities.

Challenges and Limitations of Conventional Approaches

Traditional corporate training methods, while effective to a certain extent, face several challenges. These include:

- Geographical Barriers: Traditional methods require physical presence, making it challenging to provide training to a dispersed workforce or across multiple locations.

- Scalability Issues: As manufacturing companies grow, the demand for skilled workers increases. Traditional methods struggle to scale efficiently to meet these demands.

- Standardization: Consistency in training content and quality is often compromised in traditional methods, leading to variations in skill levels among workers.

- Cost and Time: Traditional training can be costly, both in terms of time and resources. It requires trainers, and training facilities, and often results in downtime for the trainees.

The Emergence of Technology-Driven Solutions

Recognizing these challenges, the manufacturing industry has begun to embrace technology-driven solutions. E-learning platforms, virtual reality (VR), augmented reality (AR), and Learning Management Systems (LMS) have opened new horizons for training. These technologies offer several advantages:

- Accessibility: Technology-driven training can be accessed remotely, enabling companies to reach geographically dispersed employees.

- Scalability: Digital training content can be easily updated and scaled to accommodate a growing workforce.

- Consistency: LMS and e-learning modules ensure standardized training content and assessment, minimizing variations in skill levels.

- Cost-Efficiency: While there is an initial investment in technology and content creation, digital training significantly reduces long-term training costs and minimizes downtime.

- Interactivity: VR and AR offer immersive training experiences, allowing trainees to practice in a virtual environment, and enhancing engagement and retention.

The Rise of Manufacturing Training Software

Manufacturing training software, often encompassed within Learning Management Systems, has become a cornerstone of skill development. These solutions offer a diverse range of benefits, including accessibility, scalability, and standardized content.

They have transitioned from simple e-learning modules to complex, interactive simulations and virtual environments, offering immersive training experiences that closely mimic real-world scenarios.

The Impact of Industry 4.0 on Skill Development

The advent of Industry 4.0, characterized by the integration of automation, data exchange, and smart technologies, has significantly impacted skill development in manufacturing. Automation and the Internet of Things (IoT) have necessitated a more tech-savvy workforce.

This, in turn, has accelerated the adoption of training software to equip employees with the digital skills required in this new industrial era. As the manufacturing industry becomes increasingly interconnected and data-driven, training software aligns with these technological advancements, ensuring that the workforce remains competent and adaptable.

Ad: PlayAblo’s Enterprise-Grade Micro-Learning platform is built for millennial learners. Micro-Learning, assessments, and gamification features ensure learning outcome measurement and sustained engagement.

Find out more and request a custom demo!

10 Key Features of Manufacturing Training Software

As you explore manufacturing training software, it’s essential to uncover the array of features that make it a must-have for modern skill development.

1. Interactive Simulations and Virtual Environments

Imagine immersing yourself in a virtual factory, where you can operate machinery, troubleshoot issues, and make decisions without real-world consequences. Manufacturing training software offers precisely this experience through interactive simulations and virtual environments.

It provides a risk-free space for trainees to practice and refine their skills, fostering a deeper understanding of complex processes and equipment.

2. Personalized and Adaptive Learning Modules

Personalization is a key strength of training software. It tailors learning experiences to individual needs, adapting the content and pace to match a trainee’s skill level. This ensures that each learner progresses at their optimal speed, leading to more efficient and effective training outcomes.

Additionally, adaptive learning modules are designed to target areas where a trainee may be struggling, offering focused support.

3. Real-time Performance Tracking and Analytics

Gone are the days of subjective evaluations. Manufacturing training software equips you with the capability to track trainee performance in real time. You can monitor progress, identify areas for improvement, and gauge overall competency.

By harnessing data and analytics, you gain valuable insights into the strengths and weaknesses of each trainee, allowing for data-driven decision-making in the training process.

4. Cost-Efficiency and Scalability of Training Programs

Cost efficiency is a hallmark of training software. Once you’ve invested in content creation and software implementation, the long-term costs of training diminish significantly. Traditional training methods often entail ongoing expenses, such as instructor fees, travel, and printed materials.

Training software centralizes these costs into an initial investment, rendering the program scalable and cost-effective, especially as your workforce expands.

5. Mobile Compatibility

Manufacturing training software embraces mobility, enabling trainees to access training materials and modules from their preferred devices. Whether on the shop floor, at home, or during a break, trainees can engage with the content conveniently, promoting continuous learning and skill development.

6. 24/7 Accessibility

The flexibility of manufacturing training software is exemplified by its 24/7 accessibility. Trainees can learn at their own pace and time, accommodating varying schedules and shift patterns. This round-the-clock availability ensures that skill development is not limited by time constraints.

7. Immediate Feedback and Assessment

Manufacturing training software offers immediate feedback and assessments after each training module or simulation. This feature helps trainees identify areas where improvement is needed and reinforces their strengths, enhancing the learning process.

8. Content Consistency and Standardization

With software-driven training, content consistency is guaranteed. All trainees receive standardized training materials, reducing variations in knowledge and skill levels among the workforce.

9. Gamification Elements

Engagement is a critical aspect of effective training, and manufacturing training software incorporates gamification elements. Trainees can earn points, badges, or rewards, making the learning experience more enjoyable and motivating.

10. Integration with Real-world Equipment

Some advanced training software seamlessly integrates with real-world manufacturing equipment, allowing trainees to practice on the actual machines they’ll use in their jobs, enhancing the transfer of skills from training to the workplace.

The Role of Government Initiatives and Regulations

Government support is a linchpin of technology-driven skill development in the manufacturing sector. The government recognizes the importance of a skilled workforce in driving economic growth and competitiveness.

Consequently, they often introduce initiatives, incentives, and funding programs to encourage manufacturing companies to invest in training software. This support can take various forms, such as grants, tax benefits, or partnerships with educational institutions, all aimed at equipping the workforce with the digital skills required in the modern manufacturing era.

Compliance Requirements and the Impact on Training Software Adoption

Government regulations and compliance requirements are pivotal in manufacturing, particularly in areas like safety standards, quality control, and environmental regulations. These regulations have a profound impact on the adoption and structure of training software.

Your manufacturing company must ensure that its training programs align with these requirements. As a result, training software often incorporates features for tracking and reporting compliance-related training, ensuring that the workforce meets the necessary standards. Government regulations can both drive the adoption of training software and influence its design to meet specific compliance needs.

Industry Collaboration and Partnerships

Educational institutions have emerged as crucial allies in the pursuit of effective employee skills development within the manufacturing sector. They often collaborate with manufacturing companies to design and deliver specialized training programs that integrate cutting-edge training software.

These collaborations bridge the gap between theory and practical application, ensuring that the workforce is well-prepared for the demands of the industry. By working closely with educational institutions, manufacturing companies can tailor training to industry-specific needs and leverage the expertise of academic professionals.

Disseminating Best Practices and Knowledge within the Manufacturing Sector

Sharing industrial expertise, insights, best practices, and knowledge is a cornerstone of progress within the manufacturing sector. Manufacturing companies often engage in partnerships and industry collaborations to exchange insights, experiences, and innovative training approaches.

By sharing best practices, companies can collectively elevate the quality of skill development and training software implementation. These collaborations foster a culture of continuous improvement, where the wisdom gained from one organization benefits the entire manufacturing sector.

Ad: PlayAblo’s Enterprise-Grade Micro-Learning platform is built for millennial learners. Micro-Learning, assessments, and gamification features ensure learning outcome measurement and sustained engagement.

Find out more and request a custom demo!

Anticipated Trends and Advancements in Training Software

The future promises a slew of trends and advancements in manufacturing training software. From more immersive simulations to enhanced content personalization, you can expect training software to become even more effective and adaptive. With technological evolution, anticipate a continued emphasis on accessibility and the ability to meet the diverse needs of learners.

The Integration of AI and Machine Learning in Skill Development

Artificial Intelligence (AI) and Machine Learning (ML) are poised to become integral components of skill development. Imagine a system that can analyze your progress, identify areas where you need improvement, and automatically adjust training modules to address those needs. AI-driven algorithms can offer highly personalized learning experiences, enhancing your skill development journey significantly.

The Rising Potential of Augmented and Virtual Reality in Training

Augmented Reality (AR) and Virtual Reality (VR) are not just for gaming; they hold immense potential in training. Envision being able to step into a virtual manufacturing facility, where you can operate equipment, troubleshoot issues, and practice complex procedures.

AR and VR provide an immersive, risk-free environment for hands-on learning, making training more engaging and effective. These future possibilities are not distant dreams but tangible directions in which manufacturing training software is heading. The integration of these technologies will revolutionize skill development, making it more accessible, personalized, and engaging than ever before.

Final Words

The future of manufacturing training software is packed with boundless possibilities. It embraces interactive simulations, personalized learning, and real-time analytics, all while ensuring cost-efficiency and scalability. Anticipated trends like AI integration and augmented reality promise to revolutionize skill development.

Government support and compliance requirements are integral, while industry collaboration fosters a culture of continuous improvement. Embracing these facets ensures that the manufacturing workforce remains not only competent but also adaptable, positioning the industry for sustained success in a rapidly evolving world.

Ad: PlayAblo’s Enterprise-Grade Micro-Learning platform is built for millennial learners. Micro-Learning, assessments, and gamification features ensure learning outcome measurement and sustained engagement.

Find out more and request a custom demo!

Comments are closed, but trackbacks and pingbacks are open.